Adjust concrete mix designs on-site to meet specific project requirements

Achieve cost savings from reduced waste and over-ordering

Minimize project delays through rapid on-site mixing

Adjust concrete mix designs on-site to meet specific project requirements

Achieve cost savings from reduced waste and over-ordering

Minimize project delays through rapid on-site mixing

#1 Choice For Contractors In North America ⭐ ⭐ ⭐ ⭐ ⭐

Stop waiting for ready mix. Finish jobs faster.

See how this equipment works on infrastructure projects.

“We are able to get in and out of jobs quicker, that was really key. We do a lot of street patch, flowable fill for utility companies in Kansas City.

– Jimmy

Kansas City, MO

“We have reduced overtime paid to crews waiting on concrete. We can pour whenever we need it.”

– Seth

San Antonio, TX

“I don’t think concrete experience is required to run a volumetric mixer. Volumetric trucks allow us to get concrete anytime and increase overall productivity.”

-Sam

Indianapolis, IN

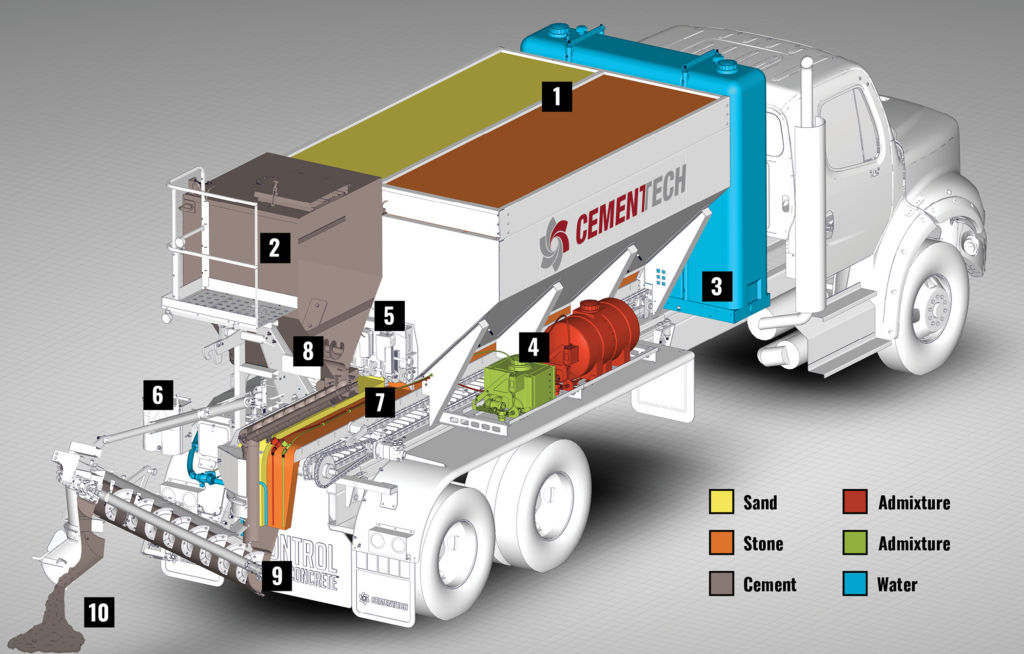

In the early 1970’s, Cemen Tech realized the advantages volumetric mixing had over traditional concrete production methods. The drawing illustrates how a volumetric mixer works.

Each concrete ingredient (sand, stone cement, water, and admixture) is contained in a separate compartment. (1) Sand and stone are stored in open bins. (2) Cement is stored in a closed, watertight bin behind the aggregates. (3) Water is provided in an auxiliary tank. (4) Conveniently located admixture tanks are integrated into the system.

Once the storage bins are loaded, the operator will select the correct mix design for that pour. (5) The sand and stone gate will adjust to their correct position, and admixture and water flow rates are set.

(6) The operator hits the start button to begin operation. (7) As the sand and stone exit their respective bins, they pass under the “strike off” gates. The materials then pass under the cement in and falls into the mixing auger. (8) The cement bin precisely meters the correct amount of cement onto the mix. The dual auger cement metering means consistent mix designs within +/-1 percent on every pour. (9) All materials simultaneously enter the continuous mixer where they are thoroughly mixed by Cemen Tech’s unique mix auger. (10) The homogeneous concrete mixture is then carried to the discharge chute. Perfect concrete is produced for each and every pour.